When you walk into a pharmacy, you will find thousands of drugs in a variety of different packaging, including capsules, plastic bottles, glass bottles, aluminum bottles, plastic tubes, aluminum tubes, and more.

Aluminum tubes are mainly used for packaging creams, ointment, gel, such as eye ointment, burn cream, dermatitis and other skin ointments, which occupy a very, very important position.

Then why do ointments need to use aluminum tubes to package? What are the special advantages of using aluminum tubes to package ointments?

What is the pharmaceutical ointment aluminum collapsible tubes?

As all know, Alumninum tubes are widely used for cosmetic, toothpaste, food, watercolor painting, glue, sealants…etc. But the most important usage is for pharmaceuticals industrial.

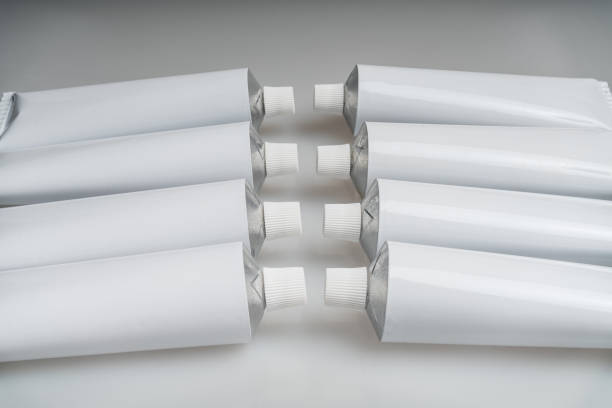

The collapsible aluminum tube is a container that has been softened and used for packaging creams, ointments and other products, it is one of the most important pharmaceutical packaging containers. Aluminum collapsible tubes can be used as the first choice of pharmaceutical ointment packaging, which can not be separated from its own superiority.

As a packaging material and container in direct touch with drugs, its material must be safe and stable. Metal is stable, but aluminum is much more stable and safe. As a pharmaceutical packaging ointment, the quality safety of aluminum tubes, the use of performance, as well as its compatibility with the drug, has a very important impact on the quality of the drug itself.

In the “National Drug Safety Thirteenth Five-Year Plan”, it is an important task to improve the level of drug quality and safety.

In order to more effectively ensure the quality of pharmaceutical packaging materials and drug safety, the State Food and Drug Administration promulgated the latest version of the YBB National Pharmaceutical Packaging Material Standard in 2015, which puts forward more standardized requirements for the management of pharmaceutical packaging materials and provides effective supervision for more environmentally friendly, safe and convenient pharmaceutical packaging materials.

What are the advantages of the aluminum collapsible tube for pharmaceutical ointment?

There are many packaging containers in the pharmaceutical industry, why does ointment like to use aluminum collapsible tube not plastic collapsible tubes?

1 . Good processing performance, strong plasticity.

The density of pure aluminum is only 2.7 grams per cubic meter, is a light metal, can be used in a variety of casting methods processing, easy to shape. In making aluminum tubes, the aluminum manufacturing process is simple and easy and the production of finished products is not easy to break, can greatly reduce processing costs conducive to energy saving. Also, it can produce tube at different size, diameter and length, different shoulder, different nozzle.

2. Corrosion resistance, good sealing

Aluminum and its alloy surface, easy to generate a layer of dense oxide protective film, can effectively isolate water, oxygen, etc., to avoid corrosion of the product in the process of circulation and use. And with the end latex of the empty aluminum hose has good sealing characteristics and more adequate sealing protection for the drugs contained inside.

3. Good thermal conductivity and good ductility.

Aluminum is a good conductor of heat, its thermal conductivity is three times greater than iron, and its electrical conductivity is second only to copper, and silver, when the cream in the hot filling, more conducive to facilitating rapid cooling heat dissipation, effectively ensure the stability of the cream.

4. Good shading and reflectivity

The polished surface of aluminum reflects more than 80% of white light, the higher the purity the higher the reflectivity, especially for infrared, ultraviolet, thermal radiation and other good reflective properties, can be used for storage on a variety of occasions, saving more storage and circulation costs, suitable for long-term display of the counter, increasing the chance of product exposure.

5. Non-magnetic, impact does not produce sparks.

This feature brings great guarantee for safe production management, and also brings high security for market circulation.

6. High barrier performance.

Compared with other non-aluminum materials, aluminum has excellent moisture and gas barrier. Generally speaking, aluminum foil thickness greater than 0.01MM, has a good moisture barrier performance. Greater than 0.015MM has gas impermeability. The increase of thickness can effectively improve the barrier performance.

The wall thickness of pharmacopoeia aluminum tubing is greater than 0.09MM or more, which is much higher than the thickness of any aluminum foil, so its barrier performance can be affirmed.

7. Good and clear printing

The smooth surface of the aluminum tube is ideal for offset printing, but not for screen printing, hot stamping, silver stamping and other printing methods. Offset printing is to put all the text artwork on one page and then print it on the aluminum tube, so the overall text is clear and easy to read, which is also very important for pharmaceuticals.

What’s the relationship between ointment aluminium collapsible tube and pharmaceutical ointment?

1. Ointment aluminum hose for a single aluminum, a stamping molding, tube and tube mouth, tube shoulder, tube body once formed, no shoulder and tube body injection joint, there is no joint injection skew, the inner layer and sub-layer peeling, welding seam separation and other potential quality risks.

2. In addition, ointment and hose in the production of annealing, external coating curing, internal coating curing, printing curing and other four times high temperature, the highest temperature of 400 ℃, in a controlled clean environment for a long time, multi-frequency dry heat baking, the risk of microbial contamination is extremely low, thus effectively ensuring that the hose to be used, with very high biochemical indicators.

3. The production of ointment aluminum hose adopts high efficiency fully automatic assembly line, which ensures unmanned operation from inputting raw materials to packaging, and all processes are formed in one time to improve production capacity. Compared with the production process of similar packaging, the process of ointment aluminum hose is reasonably coherent and complete in one go, which greatly reduces the supporting and intermediate auxiliary relief, not only saves labor costs and production costs, but also reduces the impact of human factors on the quality of pharmaceutical ointment.

Summarize.

Throughout the development of aluminum tube packaging road, not only is widely used in the field of pharmaceutical ointment, but also in a large number of applications in the field of cosmetics and food, the prospects are very broad.

Combined with the domestic development trend of drug packaging materials and pharmaceutical excipients associated with the review and approval, environmental protection, safety and convenience of drug packaging materials, will be the main direction of future development.

Ointment aluminium tube itself has many incomparable advantages, in a long period of time will not be replaced, so it will become the first choice of pharmaceutical ointment, becoming the ointment manufacturers favor.

Beauty Sky Packaging has been committed to providing qualified and high-quality aluminum tubes for all sizes of pharmaceutical companies and has been exported to more than 20 countries. Welcome your inquiry, we will work with you to provide the most reliable and safe guarantee for your products!