Do you know what’s the internal lacquer? How it is applied? Why is it used for collapsible aluminum tubes? How many types of internal coating? What’s the quality standard of the internal coating? Let’s know from this article.

What is the raw material used for internal spraying?

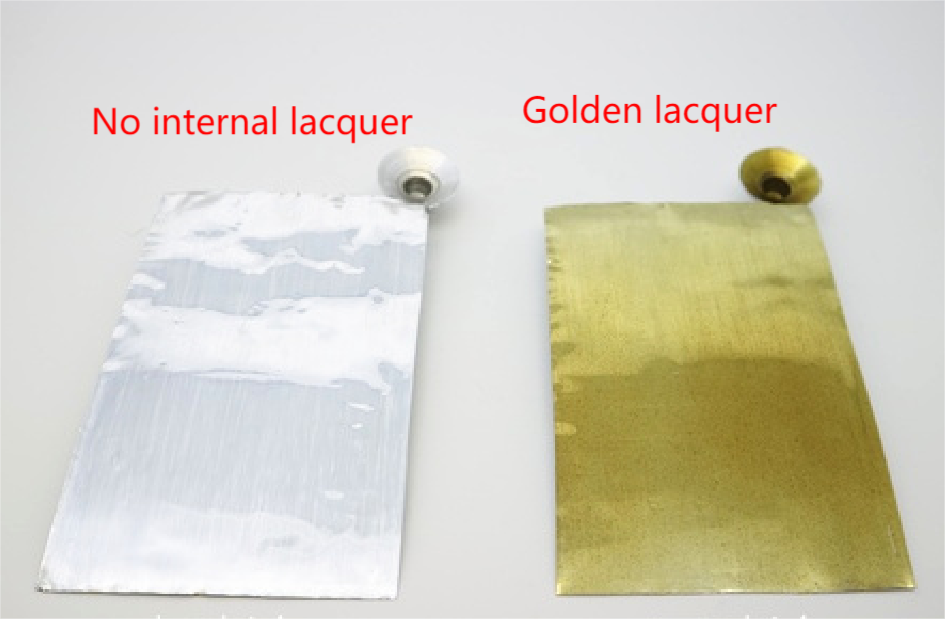

The raw material for the internal spraying of aluminum tubes is liquid called epoxy phenolic resin. This clear resin has four types: light brown (beige), golden color, transparent and special in foods. It has high resistance and can effectively isolate acids, alkalis, water vapor and solvents to avoid the reaction between the filling creams and aluminum.

The epoxy phenolic resin will come into direct touch with both the paste, which itself must be non-toxic and safe. It is common for the industry to use raw materials that meet FDA food hygiene standards. If the filled contents are foods then it also needs specific internal spraying.

What is internal lacquer ( Internal coating /Internal spraying)?

Internal lacquer calls internal spraying or internal coating in the aluminum tubes industry. Spraying is one production step in producing aluminum tubes, using a spray gun, with the help of pressure or centrifugal force, the material to be sprayed is dispersed into uniform and fine droplets, and applied to the surface of the coated object a coating method.

The “internal spraying” is the process of spraying on the inner wall of the aluminum tubes. after the empty aluminum tubes get soft by annealing, using a spray gun, the lacquer is spread uniformly into the internal wall of the soft aluminum tubes. After spraying, it needs to be baked at a higher temperature, such as 250 degrees Celsius for 5 minutes, to make the sprayed material set. It is an important process, if it is over temperature or over time, the lacquer will be too dark or too light, which will affect the quality.

What’s the main role of internal lacquer?

Anti-corrosion

Epoxy phenolic resin can effectively isolate the acid, alkali, and other substances to avoid chemical reactions between the contents and the aluminum directly.

Anti-drop

Epoxy phenolic resin is not easy to interact with metal, and it is not easy to fall off after spraying on the inner wall of aluminum.

Anti-oxidation

Epoxy phenolic resin can prevent the external environment of water, moisture, ultraviolet light, bacteria, and other substances into the paste to reduce the chances of pollution and deterioration and decay.

Which products need internal lacquer in aluminum tubes?

Internal coating is essential to the packaging effect of aluminum tubes, but not all flexible aluminum tubes need internal spraying processing. In fact, according to the properties of the filling paste, to determine whether the need for internal spraying.

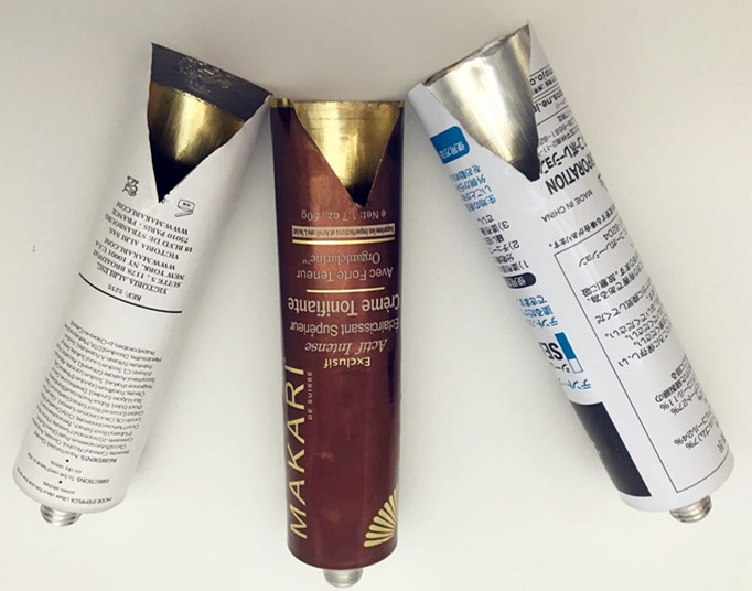

How many types of internal coatings are for Aluminum tubes?

There are four types of internal coatings for aluminum tubes. The different coatings are decided by the products the packaging tubes filling

The internal spraying is usually the following products:

1、Filling with slightly corrosive products, such as hair dyes, sunscreen, etc. Spraying can isolate the contact between the product and the aluminum to avoid unnecessary chemical reactions.

2, Sensitive and perishable products, such as moisture-hardening silicone gel, ointment, etc. Silicone rubber if filled in the sprayed aluminum hose, can improve the sealing effect of the packaging, and isolate the moisture and air, to ensure or extend the shelf life.

3, Easy to produce chemical reactions with metal products, such as pigments, shoe polish, etc.. Spraying can isolate the contact between the product and the metal to avoid chemical reactions and deterioration of the product.

4, Chemical products like glue, and adhesive will not produce a chemical reaction with aluminum, but also because of its low price, a very large part of the glue packaging aluminum tube is not required inside the spray.

It can be said that internal spraying is a very important factor affecting the quality of aluminum tubes, if the wrong internal spraying may lead to aluminum tube perforation, affecting the final use of the product.

The internal spraying process must be considered when producing squeeze aluminum tubes, but sometimes the internal coating is ignored because the supplier is unprofessional and inexperienced, or the purchaser is only focused on price. A quality aluminum tube supplier should not only have the relevant equipment and production technology for internal spraying but also be able to provide professional advice in order to produce packaging materials that meet the needs of customers.

What’s the quality standard of the internal coating?

There are 3 important testing standards for the quality of internal lacquer.

- Continuity (mA) ≤40

- Flexibility and adhesion: The lacquer doesn’t peel off and no crackle

- Lacquer chemical stability: Wipe 30 times with acetone slightly, the lacquer doesn’t peel off

Beauty Sky packaging always uses the top coating materials for the packaging tubes. Welcome to contact us