Reprinted from https://beautyskypackaging.com/how-test-quality-aluminum-tubes-packaging/

Edit date:2022-09-27

The importance of aluminum collapsible tubes in the packaging field is self-evident. This metal tube is widely used in the pharmaceutical industry, cosmetics industry, daily life products industry, learning utensils industry, chemical industry, and a wide range of uses. The proportion has slowly exceeded the plastic tube and aluminum laminated tube (ABL tube). It is even more important to buy the right good quality packaging aluminum tubes from the right supplier. First of all, to find a reliable quality supplier.

(There is a video to show how to test the quality of aluminum tube https://www.youtube.com/watch?v=pKshIjNaK9Y )

As a professional collapsible aluminum tube manufacturer, how does BEAUTY SKY PACKAGING control the quality? How does BEAUTY SKY PACKAGING keep its clients with us for decades? How do we do it? Of course, because quality has always been our top priority.

Quality control

Quality is the foundation of a company, to improve the quality of packaging aluminum tubes, all employees must participate. Every employee has the obligation and responsibility to do a good job of product quality, firmly establish the quality consciousness, and strictly control and execute the operation process of the products. Leaders and every employee are required to devote themselves to product quality management and instill quality goals into the heart of every employee. Quality is the root of enterprise survival and development.

The quality control of squeeze aluminum tubes is mainly controlled by incoming material inspection, production process, 5S site management, and final mass production inspection to ensure the overall quality of the products.

- Incoming inspection

Incoming inspection refers to the purchase of raw materials, components or products, quality confirmation and verification, that is, when the supplier sends raw materials or components, through the sampling of quality inspection, and finally makes a judgment that the batch of products is accepted or rejected. Incoming inspection is the first control of the quality of the enterprise’s products before production, such as the unqualified products into the process, it will lead to the process or the final product failure, resulting in huge losses. Incoming material inspection not only affects the quality of the company’s final product but also affects various direct or indirect costs.

In the manufacturing industry, the product quality has a direct impact on the design, incoming materials, process, storage and transportation of the four main items, generally speaking, design accounts for 25%, incoming materials account for 50%, 20% of the process, storage and transportation 1% to 5%. In summary, incoming material inspection has an overwhelming impact on the quality of the company’s products, so the quality control of incoming materials must be elevated to a strategic position to treat.

- Quality control in the production process

We call on all employees and workshop managers to participate in quality management activities. The responsibility of each process is implemented to the person, and the operation staff is strictly required to do a good job of self-inspection first, then the workshop director inspection, and then the quality inspection specialist or inspection for random inspection, to eliminate the appearance of unqualified products, and not let an unqualified product into the next process. Each workshop must make strict distinctions between products to be inspected, qualified products, and defective products to prevent mutual confusion. The products in the workshop must be placed neatly and kept clean and dry. Each workshop must standardize the operation, and strictly do not produce unqualified products, accept unqualified products, or transmit unqualified products.

- “5S” management (on-site)

The 5S management is organize (SEIRI), tidying up(SEITON), cleaning (SEISOU), cleanliness (SEIKETSU), and literacy (SHITSUKE).

Organize: It means thoroughly separating the things you want from the things you don’t want, and to put the things you want in the designated place with a sign, and disposing of the things you don’t want firmly.

Tidy up: Once the items are found to be unmarked and untreated, the site management officer will hold the person responsible.

Cleaning: It means cleaning and wiping the dust, dirt, debris, mud, and other dirty things on the workplace, environment, instruments and equipment, materials, tools and clips.

Cleanliness: It is the daily maintenance activity after the above three links. 3 minutes (or 5 minutes) before the end of each day, all the employees participate in the cleaning operation, so that the whole environment is maintained in good condition at all times.

Literacy: It is to cultivate good manners, work habits, organizational discipline and professionalism of all employees. The purpose is to create a clean, comfortable and civilized production environment, regulate the behavior of employees, and shape a good corporate image.

4. Final mass goods Inspection

The final mass goods inspection before shipment is a summary of the production products, through the whole product performance indicators of the re-inspection under AQL inspection, to confirm whether to meet the needs and expectations of customer satisfaction. The inspection must be carried out in strict accordance with the standards set by the company and the requirements of customers. Do not miss an inspection, do not hand over defective products, and do not accept unqualified products. The qualification rate of the factory will reach 100%.

At the same time, we also welcome customers to inspect the goods themselves or entrust a third-party company to inspect the goods.

How does the test of medicinal aluminum tubes?

BEAUTY SKY strictly implements the standard of aluminum medicinal hose “YBB0016 2002-2015”, and tests the produced medical aluminum tubing of ointment, the specific testing items, methods and standards are as follows.

1)Appearance

Take an appropriate amount of aluminum tube, in bright natural light, for visual inspection. Printed content should be clear and complete, correctly positioned; printing surface should be smooth and clean, with 50% ethanol dipped in degreasing cotton lightly wipe the aluminum tube printing surface 30 times, there should be no decolorization; aluminum hose should be clean, the tube should be free of processing debris and other foreign matter; will be repeatedly rotated up and down the cap and mouth 10 times, under the conditions of twice the magnification to observe, there should be no metal debris.

2)Internal lacquer & primer flexibility and adhesion

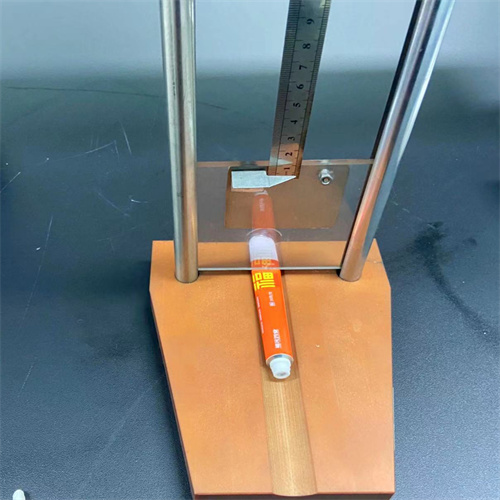

Take the appropriate amount of empty aluminum tubes, set on the rod, the tail of the tube set on the first level of the ladder corresponding to the specifications of the aluminum tube, the rod is extended from the mouth, the aluminum tube in the entire test process should have been in a vertical state with the base, the top pressure plate set on the extended rod and let it gently rest on the top of the mouth, apply uniform pressure on the pressure plate, quickly squeeze the aluminum tubing downward, the aluminum tube should be presented uniformly folded “accordion” appearance, remove the pressed aluminum tube from the bar, stretch it as close to the original length as possible, cut it open longitudinally, observe the surface of the inner and outer coating, the inner and outer coating should be free of cracks and peeling.

3)Caps fit on aluminum tubes excellently

Take the right amount of aluminum tube, turn the cap and the nozzle up and down 2 times, and the thread fit of the aluminum hose should be suitable. Aluminum hose and the cap fit – through the cap fit test to verify, including the flatness after screwing on the cap, the cap lock or open the tightness, etc. On the one hand, the cap can prevent the spillage of the drug in the hose, on the other hand, it can prevent foreign objects from entering the hose. The barrier and sealing of the overall packaging of the aluminum hose depend largely on the compatibility of the hose and the cap, so if the cap is poorly matched, the drug is prone to leakage and deterioration.

4)Evenness of end latex

Take an appropriate amount of this product, in bright natural light, visual inspection. Aluminium hose tail coating (end latex) surface should be uniform, with no hanging. Of course, some customers like unequal end latex, and some customers also have requirements for the width of the tail coating, depending on the needs of customers and making the corresponding testing standards.

5)Sealability

Take an appropriate amount of squeeze aluminum tubes, install the tube cap and immerse it in 10-30℃ water, the end of the tube is about 10mm from the water surface, then use the conical filler to apply 0.2Mpa air pressure at the open end of the tube, and there should be no air bubbles within 5 seconds of immersion in the water.

The sealing performance is verified by the airtightness test to find out the location of the aluminum hose where the air leakage occurs to prevent the packaged ointment from being oxidized or even leaking due to poor sealing. Especially for the open aluminum tube is more important, although the empty aluminum tubes filling paste object is not as easy to leak as water, but as very important and must test the sealability.

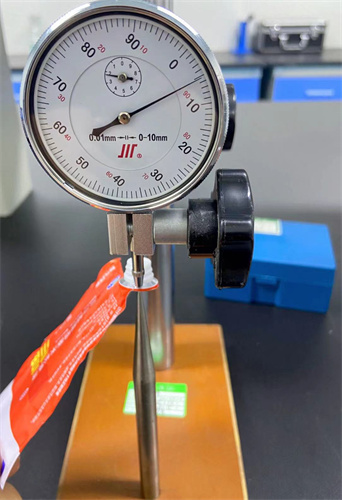

6)Inner coating (internal lacquer) continuity

Turn on the power of the instrument for the internal coating continuity test, the red indicator light on the panel, press the calibration button to calibrate the circuit: press the calibration button continuously, and at the same time put the range selection switch at 5mA, 50mA or 500mA respectively, adjust the instrument so that the pointer deflection is within 10% of 1.8mA, 18mA or 180mA respectively, release the calibration button, the instrument calibration is completed. In order to protect the instrument and avoid overload, put the range selection switch at 500mA when start reading. take the proper amount of this product, screw on the tube cap, and inject the test liquid into the aluminum tube (weigh 10g of copper sulfate, 0.05g of sodium dicaprylate sulfonate, add 0.5ml of ice acetic acid, add water to 1000ml) to 10mm from the mouth, put the nozzle and shoulder part of the aluminum tube into the V-slot of the base electrode, and put the sliding electrode into the V-slot of the base electrode. and slide the sliding electrode downward into the aluminum tube, adjust the height of the sliding cone so that the aluminum tube and the swing electrode remain coaxial, press the test button and determine the appropriate test range as soon as possible, and read the data after 5 seconds, use the same test solution no more than 8 times, the current display shall not exceed 40mA.

7)Chemical stability of inner coating (internal lacquer)

Take an appropriate amount of these flexible aluminum tubes, cut and level along the longitudinal direction of the tube body, and lightly rub the inner coating with a degreasing cotton ball dipped in acetone 30 times, and the coating should not fall off.

The stability of the coating is verified by the chemical stability of the inner coating. After packing the ointment medicine with the aluminum hose, the inner coating of the aluminum hose is in direct contact with the medicine, if the chemical stability of the inner coating material is poor, it is easy to fall off after contacting the medicine, and then pollute the medicine.

8)Toughness

Take several soft aluminum tubes, placed in the positioning slot of the toughness test device (aluminum tube such as the diameter of the tube body is less than 16mm, it will be placed on the additional plate), so that the end of the aluminum tube and the stopper contact, release the gate, let the gate fall to the body of the tube, read the top of the gate on the scale number, should be in line with the provisions of the following table.

Use of aluminum pharmaceutical ointment container packaging of drugs, in transport, storage, sales process, inevitably will be subject to external extrusion and collision, if the aluminum soft rod tube toughness is not good, prone to rupture, leakage. It will not only pollute the same kind of products but also affect sales and cause waste. And bad toughness will lead to poor sealing, sealing occurs leakage leads to microorganisms into the drug, be purchased by patients may cause skin allergies, redness and other problems. Therefore, the toughness test of aluminum pharmaceutical ointment tubing is very important.

Aluminum tube toughness test can be seen in this video.

The standard requirements for pharmaceutical packaging materials also point out that the mechanical properties of the flexibility and adhesion of aluminum hose should be tested. You can use the coating flexibility and adhesion force tester RX-N, which also meets the requirements of the standard YBB00162002-2015 “Aluminum pharmaceutical ointment tube”.

9)Bacteria inspection

Take 10pcs the pharmaceutical aluminum tubes, respectively, add 2/3 of the labeled volume of sodium chloride injection, shaking for 1 minute, that is, the test solution, the test solution for membrane filtration, according to the inspection (“Chinese Pharmacopoeia” 2015 edition of the four general rules 1105,1106), the number of bacteria shall not be more than 100 CFU per branch, mold, yeast number shall not be more than 100 CFU per branch, shall not be detected Staphylococcus aureus, Pseudomonas aeruginosa.

(10) Sterile (for surgery, burns and serious wounds with ointment packaging tube)

Take 10 medicinal aluminum tubes, respectively, add the labeled volume 1/2 of sodium chloride injection, shaking for 1 minute, combined extracts, according to the law to check (“Chinese Pharmacopoeia” 2015 edition of four general 1101), should meet the provisions.

(11) Abnormal toxicity

Take 5 medicinal packaging metal tubes, add the labeled volume of sodium chloride injection, shake for 5 minutes, combine the extracts, and check according to the law (Chinese Pharmacopoeia 2015 Edition IV General 1141), shall comply with the provisions.

(12) Primary skin irritation

Take 5 empty aluminum tubes for medicine, add the labeled volume of sodium chloride injection, shake for 5 minutes, combine the extracts and set aside, and check according to the primary skin irritation test method (YBB00072003-015), there should be no irritation reaction.

(13) Dimensions inspection

Most of the above tests are functional tests of aluminum collapsible tubes, but the top and first important premise are that the dimensions of the products are correct from the requests, including the diameter, length, thickness, thickness of the shoulder, and weight of the test, which are decided when the order is placed.

We will buy the corresponding aluminium ingots according to the diameter, length, and thickness of the metal packaging tube, as long as the order is placed correctly, and our products are produced by fixed molds and machines, the production process is also in accordance with the standard work, there will not be problems in general, there will be some allowable tolerances in the production process, which is also acceptable to customers. However, we still need to check according to the order accordingly at the beginning of production.

14)Closing film for sealed orifice tube

For sealed orifice aluminium tubes, there will be a film left in the production process that needs to be pierced with the cap It is wrong if the film is too thick, the customer can’t pierce it easily. We must make sure the film has the right thickness.

If you need to get the exact latest COA ( certification of analysis for empty aluminum tubes), please e mail us today, we will provide all the information you are interested. Thanks in advance!

BEAUTY SKY PACKAGING all staff in the spirit of product responsibility, to each customer responsible for the work attitude, and strive to do the best supplier of aluminum pharmaceutical hose in China, the Made in China to the world.