When it comes to production, there are so many areas that are involved. However, it seems that the content is paid the most attention, and for a good reason. For example, when it comes to cosmetic and hair care products that have direct contact with the consumer’s skin, there need to ensure that the chemical components are safe.

Still, there are other areas involved in the production process that deserves as much attention. One of these is the packaging. While it may seem like the least important thing, it should be treated with importance. In an industry like cosmetics, there is an endless list of reasons why cosmetic packaging materials should be treated as important.

Packaging can be defined as the science, art and technology of protecting products and materials for their storage, transportation and use. This definition is encompassing as it summarizes the major reasons why packaging is important. Science because of the chemical composition, art of its appearance.

Here are some of the reasons why the packaging process should be treated very importantly

· Content Contamination –

Improper packaging tubes or other packaging material could lead to the contaminated o product. If the product is not sealed properly, or there are any openings in the packaging, it could lead to foreign contaminants getting into the product. This is a major concern as it could mean that the consumer is applying a contaminated product to their skin.

Some materials can lead to the contamination of their contents of certain chemicals are present in these contents. These contaminations could be so severely dangerous to the customers, a problem that should largely be avoided.

· Leaks –

Similar to contamination, if there are any leaks in the packaging of contents, the content of high quality could end up with poor quality at the end of the day if the packaging process is not taken with seriousness.

· Environmental Pollution –

Asides from posing a threat to the customer directly, packaging tubes or containers could also lead to environmental pollution. This is one of the reasons why any environmentally conscious food, toothpaste, cosmetic and other product manufacturer would slowly shift from plastic material and are move towards other recyclable materials. These materials include aluminum tubes for packaging.

For example, plastic packaging tubes have been proven to lead to a large amount of waste and have been placed responsible for some harmful chemicals seeping into the environment. While measures are being employed to increase its recyclability, it is most advisable to move to other available options, like aluminum tubes.

This is because some groups of scientists researched and found that even the plastics that were labeled as biodegradable would stay in nature and still maintain the same nature thereby posing the same threats as the non-biodegradable.

· Physical Appearance –

Health benefits both immediate and towards the environment are both very important. However, another thing to consider is the outward appearance of these containers. These include the color, the shape, the True enough that this does not affect the content but there is a role that appearance plays in the marketing of a product.

This feature is very important in the cosmetic and food industry. Cosmetic packaging materials like the packaging tube should have an appearance that also appeals to the customer as much as the content would. As simple and irrelevant as that might seem, it plays a big role in the marketing of these products

When it comes to collapsible tubes (squeeze tubes), the aluminum collapsible tube is slowly gaining recognition. This is due to the many qualities that the aluminum collapsible tube possesses and the many boxes that it ticks when it comes to benefits. They can be used for cosmetic packaging and these tubes come in various shapes and sizes.

Here is a list of some properties and how aluminum collapsible tubes exhibit them.

· Chemical Composition Safety –

Aluminum is used in so many industries for the production of a wide range of materials, from aluminum tubes to automobiles. One of the properties responsible for that is the fact that aluminum hardly has an interaction with the chemical composition of its component. This property is most useful in the cosmetic industry as the products usually have direct contact with the consumers. This means that even a minute level of toxicity could have adverse effects on the consumers. Hence, when it comes to cosmetic packaging tubes, the aluminum collapsible tube is a wise option for tube packaging.

· Durability –

Although this seems quite similar to the chemical composition safety, they are a bit different. Aluminum collapsible tubes have a long shelf life implying that you hardly have to worry about the packaging tube deteriorating when the contents are in good condition.

In simpler words, aluminum tubes for cosmetics and other products are durable and sustainable. This is another reason why collapsible aluminum tubes are great tubes for cosmetic packaging and other forms of tube packaging

· Recyclability –

The aluminum collapsible tube is the most recyclable form of packaging tubes with recyclability of 80% (it is highly recyclable) this form of tube packaging ensures that the level of environmental pollution is reduced to a considerable amount thereby contributing to a very healthy ecosystem. A cosmetic product manufacturer who is very environment-conscious would have no problem with using aluminum collapsible tubes as a cosmetic packaging option.

· Appearance and Variability –

While these are two different properties, they can be collated into one point. Appearance mainly has to do with how appealing the physical structure of the tube is. Variability checks the variety of sizes in which these tubes could come in. Aluminum collapsible tubes tick both boxes effortlessly.

Aluminum tubes for cosmetics ( cream, lotion, etc.) and other products (like food substances and even toothpaste) come in various shapes and sizes and the body can be customized to suit the brand color and other factory uniqueness. These features ensure that the product is not just of great quality but that consumers would love to pick them when placed on the counter making it especially helpful as tubes for cosmetics

· Affordability –

Aluminum collapsible tubes are generally affordable. One would think due to their value that they are made of materials like gold or silver but Aluminum is a cheap material that is abundant and this is why it makes aluminum collapsible tubes perfect packaging tubes for cosmetics.

In conclusion, the many reasons stated above make aluminum collapsible tubes perfect packaging tubes for cosmetics. There are other reasons as well but these are some of the most important points to note. Aluminum collapsible tubes are great due to their durability, recyclability, affordability and of course how they improve the appearance of the cosmetic product.

There are many reasons why aluminum collapsible tubes make perfect packaging tubes for cosmetics. One of the main reasons is that they offer chemical composition safety, which is essential in the cosmetic industry. Aluminum tubes are also durable and recyclable, which makes them environmentally friendly. They come in a variety of sizes and shapes, making them perfect for any cosmetic product. Lastly, they are affordable, making them an economical option for packaging cosmetics. these tubes would have a huge price tag however, the case is the opposite.

One of the reasons for this is the fact that it is highly recyclable. It has also been discovered that it is less expensive to recycle aluminum rather than the primary production of bauxite. This contributes to the reduction of the cost of production in both the short and long run.

· Availability –

It is one thing for a product to have various advantages, and another thing entirely for it to be available. Aluminum collapsible tubes are both very helpful and available. When it comes to aluminum tube packaging production, it is impossible not to get a factory. With locations all around the world (China especially), collapsible aluminum tube is not scarce.

You can also get them in large numbers, and various sizes and they can be customized to suit the request.

. Zero waste

Cosmetics are expensive, end-users like to use them to the last drop, and aluminum tubes are the best packaging tube to save money.

Conclusion

Packaging material should be taken into very much consideration as much as raw material for production is. This is because packaging material can affect the quality of the products at the end of the day. For example, a poor cosmetic packaging material would be a ticket to ending up with poor content. From chemical composition to durability, there is an endless list of the adverse effects that they could have.

For products like cosmetics that have a large market and direct contact with the consumers, extra care should be taken.

Aluminum collapsible tubes, packaging tubes for cosmetics, toothpaste, food, and other products are both wise and easy options. From environmental safety to durability, aluminum tubes tick all the boxes and leave the manufacturer at an advantage.

How Aluminum Squeeze Tubes Are Made

Aluminum is a popular metal when it comes to the production of several things and for a good reason. The 13th element on the periodic table, this silvery-white metal is the most abundant metallic material in the Earth’s crust and the most used nonferrous metal.

Here are some of the properties that make Aluminum desired by many manufacturing companies.

· Density –

Aluminum is a lightweight metal with a density lower than coppers. This light nature of aluminum is what makes it desirable to many automobiles and even other industries that make collapsible aluminum tubes. This is because it is very malleable (i.e. it can be easily beaten into different shapes)

· Strength to weight ratio –

Although this property can be attributed to its low density, they are two different things entirely. The strength to weight ratio of aluminum is high implying that despite the lightweight of this material, it performs as well as other metals and is even better when it comes to its overall strength.

This again makes it desirable, most especially cosmetic packaging.

· Corrosion –

This is perhaps one of the major problems with so many metals. Hence, this is a property that must be thoroughly evaluated before the metal in question is employed in the production process. Corrosion is the irreversible deterioration of metals that results from the interaction with its immediate environment. Aluminum is one of the metals that are resistant to this phenomenon. This is as a result of the ability of aluminum to form an oxide on its surface and this in return prevents corrosion from occurring.

· Durability –

Aluminum is a very durable metal hence ensuring that whatever it is used in manufacturing has a very long shelf life. This is most useful in cosmetic and food industries with delicate products. They usually employ aluminum containers (e.g. aluminum collapsible tubes as cosmetic tubes or hair care product tubes) as it guarantees their content is able to stay on the shelf for as long as it can without having to worry about the container.

· Recyclability –

The world is becoming more conscious of the state of the planet. This is a great thing as it ensures that the next generation is not left to suffer the build-up of many problems and a destroyed ecosystem. One of the ways in which this is implemented is the reduction of waste by the use of biodegradable or recyclable materials. Aluminum is one of the materials that tops the chart when it comes to recycling with recyclability of 80%.

· Casting –

Apart from being malleable, aluminum is a metal that can be cast into various shapes and sizes. This again makes it so versatile in its area of use, why it can be employed by various manufacturers.

Aluminum is used in the production of many materials and instruments. It is used in automobile production processes and can be found in bicycles and even aircraft. It is also used in the production of pots and packaging materials like collapsible tubes for packaging industries.

Collapsible Tubes (squeeze tubes) are tubes with thin walls and cylindrical profiles that can be collapsed, as their name implies. They are majorly used for storing viscous liquids like gels, cosmetic products, drugs, sauces, and most commonly toothpaste.

A collapsible Tube is made of several materials ranging from plastic to metal like tin and aluminum. Aluminum squeeze tubes are in high demand in the market presently thanks to so many advantages ranging from durability to its recyclability. The process of manufacture is also environmentally safe and poses no threat to humanity and the ecosystem at large

Here’s how Aluminum collapsible tubes are made:

· Metal slugs are pieces of metal that are gotten from perforating, piercing, or even punching. With the right diameter of 99.7% pure aluminum slug to make the right diameter of the aluminum tube. These metal slugs are lubricated in order to make sure that the next process goes on smoothly. The extra edges are also eliminated and this is to make sure that they come out both glossy and smooth in preparation for the next process.

· This process is known as the extrusion. The extrusion is a process in which the slug is formed into the tube

· After the tube is formed, it is cut and trimmed to the required size. This is because like other forms of packaging, aluminum collapsible tubes come in standard sizes

· In the next process, the tube is subjected to an annealing oven. This is to ensure that they are collapsible like their name implies

· The inner part of the tube is then coated and cured with an inner baking oven with a temperature of about 300⁰C. This procedure is to ensure that the inner part of the tube is glossy and the content is also protected

· The base coat is then applied to the tube and then dried in an oven of about 200⁰C

· After the base coat has dried successfully, the tube is then printed up to 5 times over the base coat. Then it is dried in a drying oven of about 200⁰C

· The capping process directly follows the drying of the tubes. The caps are applied to the tubes with the required force

· The base of the tube is then sealed with latex (rubber). It is essential to seal both sides to ensure that there is no leaking from either side

Conclusion

When it comes to aluminum collapsible tubes packaging tube for cosmetics (lotion, cream), food, and even pharmaceutical products (toothpaste), you can never go wrong with aluminum collapsible tubes. Aluminum on its own is a very functional metal that is laced with so many favorable processes that aid its use for the production of collapsible tubes.

For example, the casting and malleable property of aluminum are what aid the formation of the slug into the empty aluminum tubes. It is made from the right dimension and weight of aluminum slug.

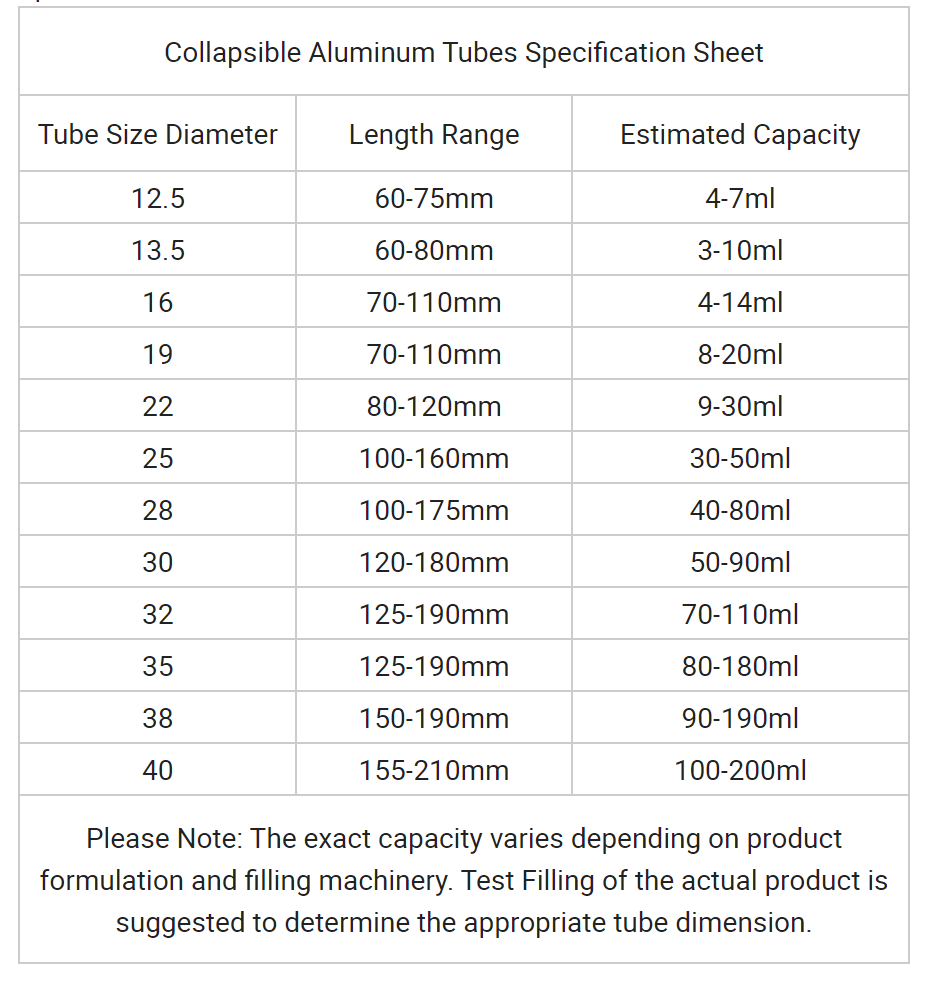

Aluminum Collapsible Tube comes in various shapes and sizes and can be customized to suit the taste of the manufacturer and the consumer. They also have a high manufacturing market as aluminum is not hard to come by, and the recyclability aids reuse for a good number of times. The volume has 3.5ml, 5ml, 10ml, 15ml, 30ml,45ml, 50ml to 200ml; Cap is various shapes and dimensions; Diameter has 13.5mm, 16mm, 19mm, 22mm, 25mm, 28mm, 30mm,32mm, 35mm, 38mm, 40mm.

Affordability, durability, and the fact that the production processes are safe to both the customer and the environment is enough reason to settle for this tube for cosmetics and other various products.